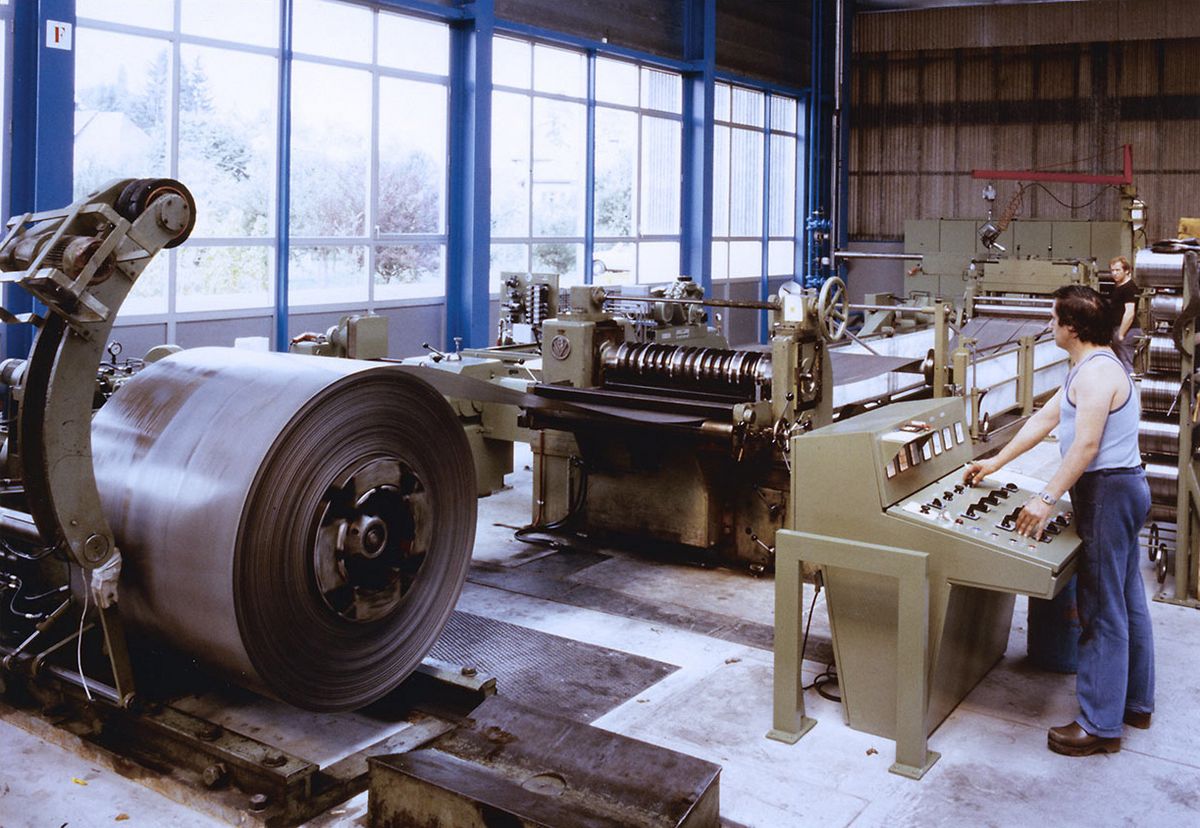

Using lean tools on our Bihler GRM-NC systems enables us to produce busbars with a material thickness of up to 4 mm, depending on the component size, cost-effectively and with minimal material consumption. We generally optimise the geometry with our customers in order to achieve the highest possible process reliability.

More complex busbars, on the other hand, are manufactured using modular progressive tools on our automatic punching machines. Using both production concepts, we are able to produce both small series starting at 50,000 pieces and large series with several million parts. We use prototypes and pre-series that have been cut by laser or micro water jet in the development process.

Using lean tools on our Bihler GRM-NC systems enables us to produce busbars with a material thickness of up to 4 mm, depending on the component size, cost-effectively and with minimal material consumption. We generally optimise the geometry with our customers in order to achieve the highest possible process reliability.

More complex busbars, on the other hand, are manufactured using modular progressive tools on our automatic punching machines. Using both production concepts, we are able to produce both small series starting at 50,000 pieces and large series with several million parts. We use prototypes and pre-series that have been cut by laser or micro water jet in the development process.

Using lean tools on our Bihler GRM-NC systems enables us to produce busbars with a material thickness of up to 4 mm, depending on the component size, cost-effectively and with minimal material consumption. We generally optimise the geometry with our customers in order to achieve the highest possible process reliability.

More complex busbars, on the other hand, are manufactured using modular progressive tools on our automatic punching machines. Using both production concepts, we are able to produce both small series starting at 50,000 pieces and large series with several million parts. We use prototypes and pre-series that have been cut by laser or micro water jet in the development process.

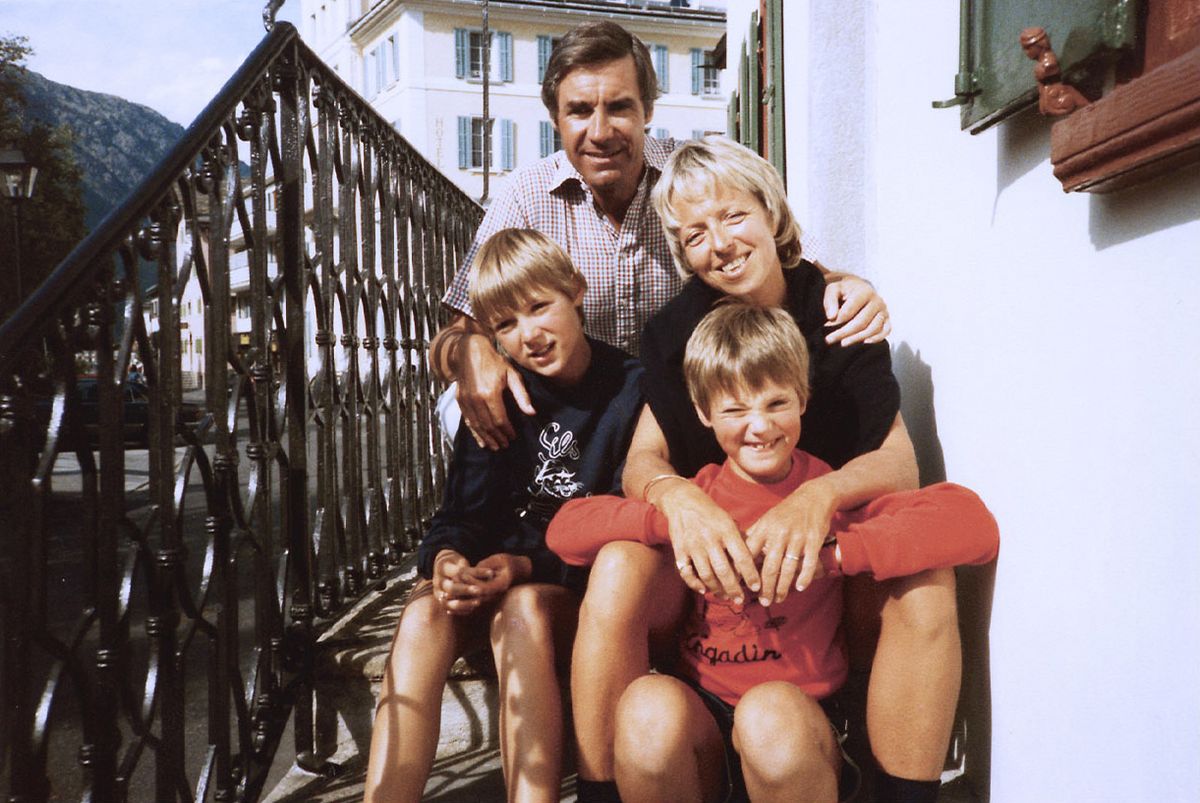

![[Translate to en:] FIR Group Geschichte [Translate to en:] Johanne Wirz - FIR Group Geschichte](/fileadmin/images/fir-group/geschichte/johannes-wirz.jpg)